Case Studies

Overburden & Stripping Surveys

Visually and quantitively verify contractors reports for overburden removal. Once approved the overall quarry surface can be updated reflecting the new changes.

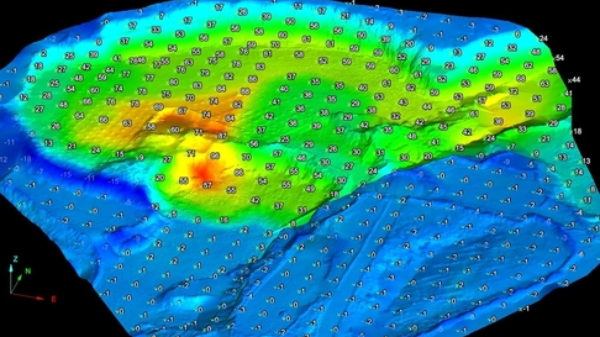

Change Detection Scanning

Create customized data ranges to determine the distance of change and visualize the variance. This can be useful for overburden, reclamation, shotcrete depths, or tracking movement of material.

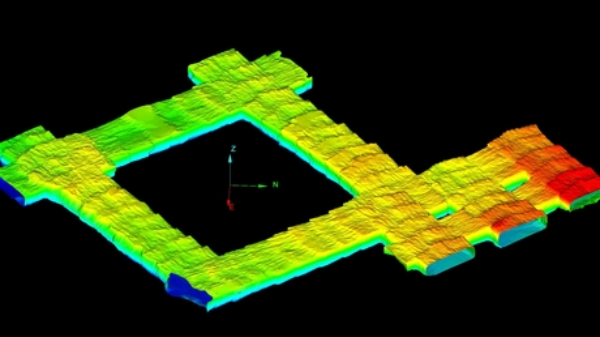

Shed / Barn Stockpile Example

Material storage enclosure scanned and processed, every material shed or barn presents a unique survey challenge. Custom structural surfaces can be modeled in these areas allowing consistent, repeatable measurements with each measurement.

Stockpile Yard Example

Point clouds from LiDAR and rendered surfaces used for volume calculation. If the site has tunnels and feeders these can be modeled to provide more exact volume measurements as the stockpiles change over time.

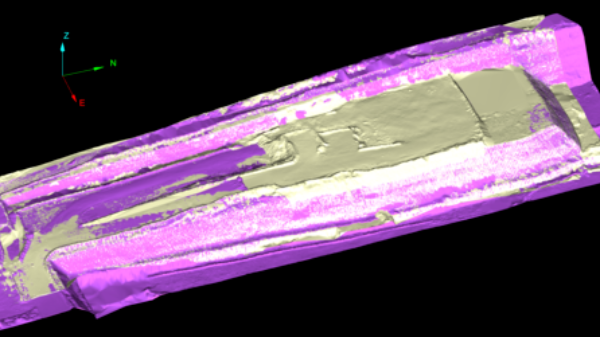

Overburden / Stripping Example

An overlay of the point clouds captured from a LiDAR UAV / Drone is made into strips and overlaid on the final rendered surface. Being able to determine ground surface from the tops of trees and vegetation is critical for volume calculations.

Dome Inventory Example

Stockpile inventory example in a dome. Data is captured in minutes and can give visual insights and measurements of the current dome or silo stockpile.

Room and Pillar Scanning

Using static and dynamic LiDAR systems we are able to map, measure, and track room and pillar progress. LiDAR and processing data allows for enhanced visualization of areas of interest and more precise volumetrics.

Stockpile Surface Example

A stockpile yard at a port scanned and processed, the rendered surfaces ready for volumetric modeling. Point cloud data can be created from UAV / Drone and combined with LiDAR data.

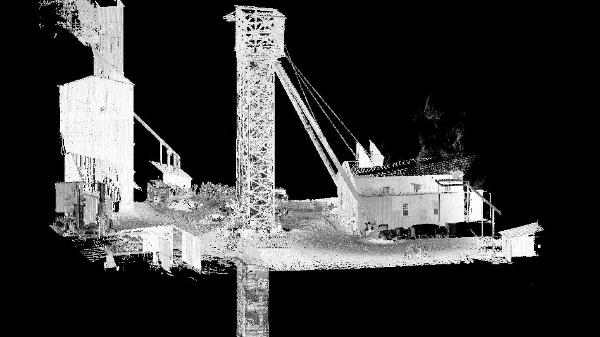

Mine Shaft Scanning

Shaft scanning has been used for rehab, repairs, change detection, and historical mapping. The ability to mount our dynamic LiDAR system to a cage and map shafts effectively, safely, and quickly means lower amounts of downtime in hoist operations.

Interested in learning how Wingfield can help your business?

Schedule a conversation with a wingfield specialist!

or call 423-698-0100