Your next equipment failure isn’t a possibility. It’s a certainty.

Your gut can sense it coming (just like last time).

But what about your outdated monitoring system?

It will spot it exactly when it always does: TOO LATE.

The Hard Truth:

…of companies suffer surprise equipment failures — even with regular inspections

(Baker Hughes Research)

…of industrial businesses face unexpected outages every month

(Drives & Controls Report)

…of flaws go undetected by human inspectors during visual checks

(Averroes Study)

That’s where Wingfield’s 4DNA technology turns the impossible into inevitable:

predictable, preventable, profitable asset protection.

Your mills, kilns, furnaces, and refractory-lined equipment?

They’re about to get an upgrade that changes everything.

But first, let me show you why traditional asset inspection methods are becoming obsolete in 2025 (and what that means for your facility)

Your Plant’s $2.1M Dollar Breaking Point

When that irreplaceable engineer with 30 years of knowledge retires next year… which disaster do you choose?

Right now, your facility faces two dangerous options:

Choice 1: Shut Everything Down At Your Operation

This means shutting down kilns for inspections and stopping your mills completely. It even means sending teams into hazardous areas. (Creating costly downtime with every check… and making your insurance agent reach for anxiety meds)

Choice 2: Keep Running Blind

This means ignoring subtle erosion and deformation problems until they become catastrophic failures. Your structural shifts keep developing right under your nose.

Every hour your refractory lining thins is another $10,000-$15,000 in potential damage with unplanned downtime (costing industrial manufacturers an average of $120,000 per day…)

And those “advanced” monitoring systems you invested in?

They’re actually doing their job… but here’s what nobody told you when you bought them – they’re only capturing 23% of the critical data you need to make bulletproof decisions:

- Your current sensors work – but they can’t see the signatures that predict failures months in advance…

- Your vibration monitoring collects data – but it’s missing the patterns that reveal what’s really happening inside your equipment…

- Your manual inspections cover the basics – but they’re limited to surface-level issues when the real problems are brewing where human eyes can’t reach..

- Your maintenance schedule keeps things running – but without the missing data layer, you’re still playing guesswork instead of chess…

The truth is, you don’t need to rip out what you’ve built. You just need to add the one piece that transforms your system into an unstoppable early-warning machine.

Traditional asset protection methods just don’t cut it anymore.

THE OLD WAY STOPS HERE

THE FUTURE LINKS NOW

Welcome to Predictive Asset Protection 2.0 by 4DNA

Finally: Spot Equipment Issues the Moment They Start

Imagine if you had complete control of your infrastructure’s future.

Plants can now justify what they need to do because they’re seeing the hard data.

They’re using technology that eliminates speculation and makes their decision making crystal-clear.

4DNA transforms everything about how you protect your operation.

- It sees deep into your equipment (catching microscopic changes months before they become problems).

- It remotely puts your engineers inside your infrastructure (virtually walking through areas with precision human eyes could never capture).

- It records decades of expert knowledge (preserving your best engineer’s insights even after they retire)

- It turns maintenance into a competitive advantage (while competitors guess, you know exactly what’s happening)

Developed with our partner 4D-Delta

Here’s Exactly What 4DNA Predictive Maintenance Means For You:

True Predictive Maintenance

Transform weeks‑early warnings into instant fixes (and avoid million‑dollar surprise problems)

More Production

Monitor all your infrastructure with 4DNA to eliminate costly shutdowns (When every hour of downtime costs North American facilities $242,000, every hour saved means serious money earned)

Operational Cost Mastery

Optimize your entire maintenance budget (Watch your cost‑per‑ton drop year after year)

Future‑Proof Protection

Move from crisis management to strategic planning (Finally get ahead of maintenance challenges)

These benefits sound impressive. But what makes them possible?

Let me show you what sets 4DNA apart..

The Wingfield 4DNA Difference: Five Firsts in One Solution

We’ve combined what no one else in North America has: 87 years of expertise, military-grade LiDAR, and predictive technology that sees insights about your assets that no one else can see.

It’s wear management for the digital age:

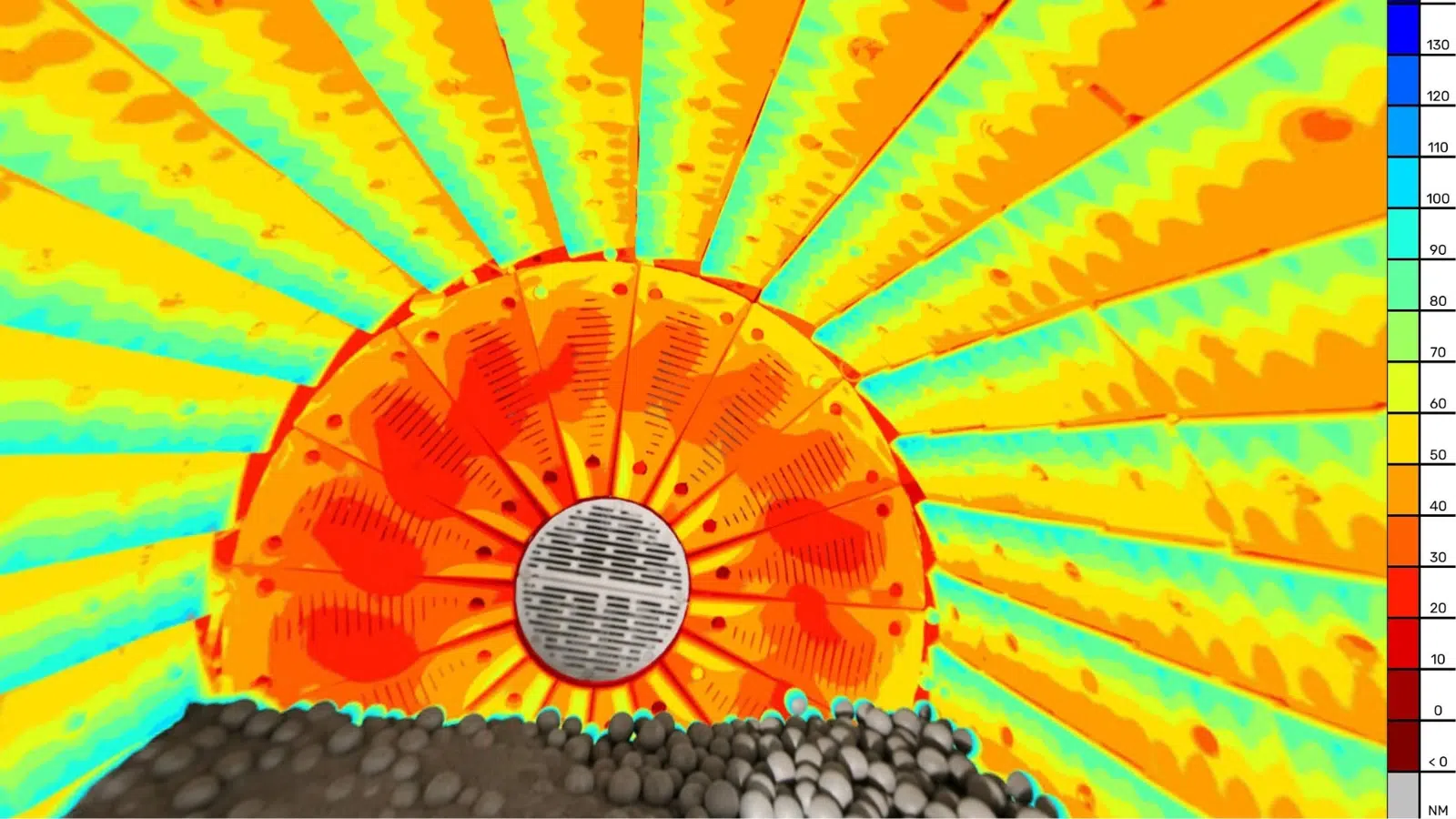

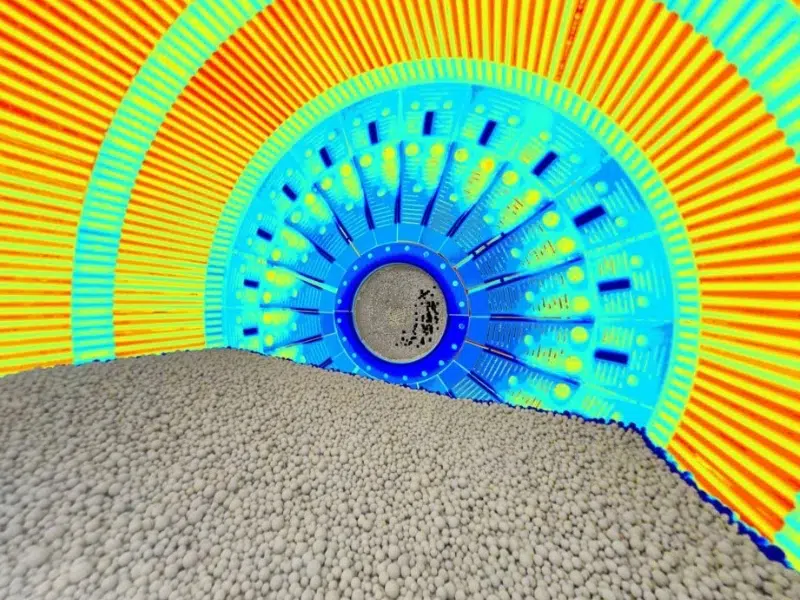

Advanced Virtual Reality (VR) in The Hands of Your Team

What happens when Military-grade LiDAR precision meets advanced asset management? All your engineers gain superhuman diagnostic capabilities. How? We capture and process remote sensing data. Next, we deliver it via cutting-edge VR that extends the reach of your team beyond physical limitations.

Your Equipment’s Performance, Backed by MASSIVE Intelligence

4DNA transforms fragmented maintenance knowledge into a unified intelligence hub. Every team member (from the field to the boardroom) can access important data points and contribute to your organization’s collective asset intelligence.

Decades of Expertise To Solve Tomorrow’s Challenges

Nearly a century of measuring critical industrial processes (since 1937) means we understand your operation. Our experts have solved measurement challenges across every major industry.

End‑to‑End Protection Without the Complexity

Tired of cobbling together subjective solutions and protection that leave gaps in your objective decision-making? While others force you to piece together add-ons and extras, we deliver one system that just works. One team handles everything from setup to support.

NORTH AMERICA’S FIRST MOVERS

Be among the first to leverage 4DNA technology in North America and gain a competitive edge right now. (Start leading your industry’s transformation today).

Want to see exactly how this works?

Let me take you behind the scenes of 4DNA in action..

How 4DNA’s Asset Inspection & Predictive Maintenance Works in 4 Steps:

From Scan to Action

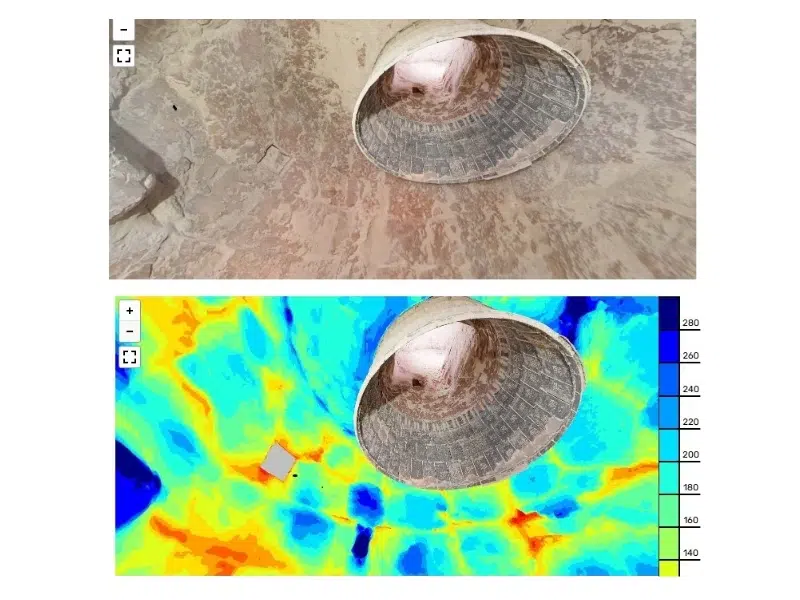

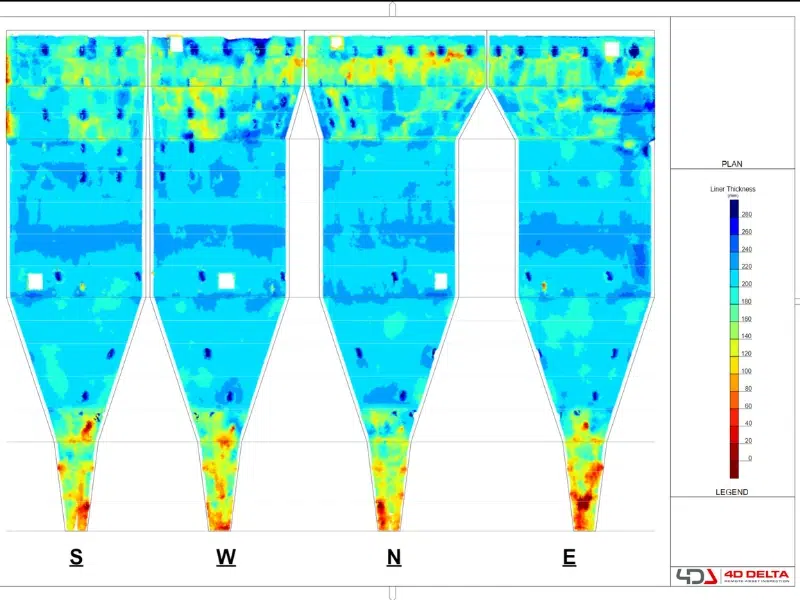

Step 1: We Scan Everything

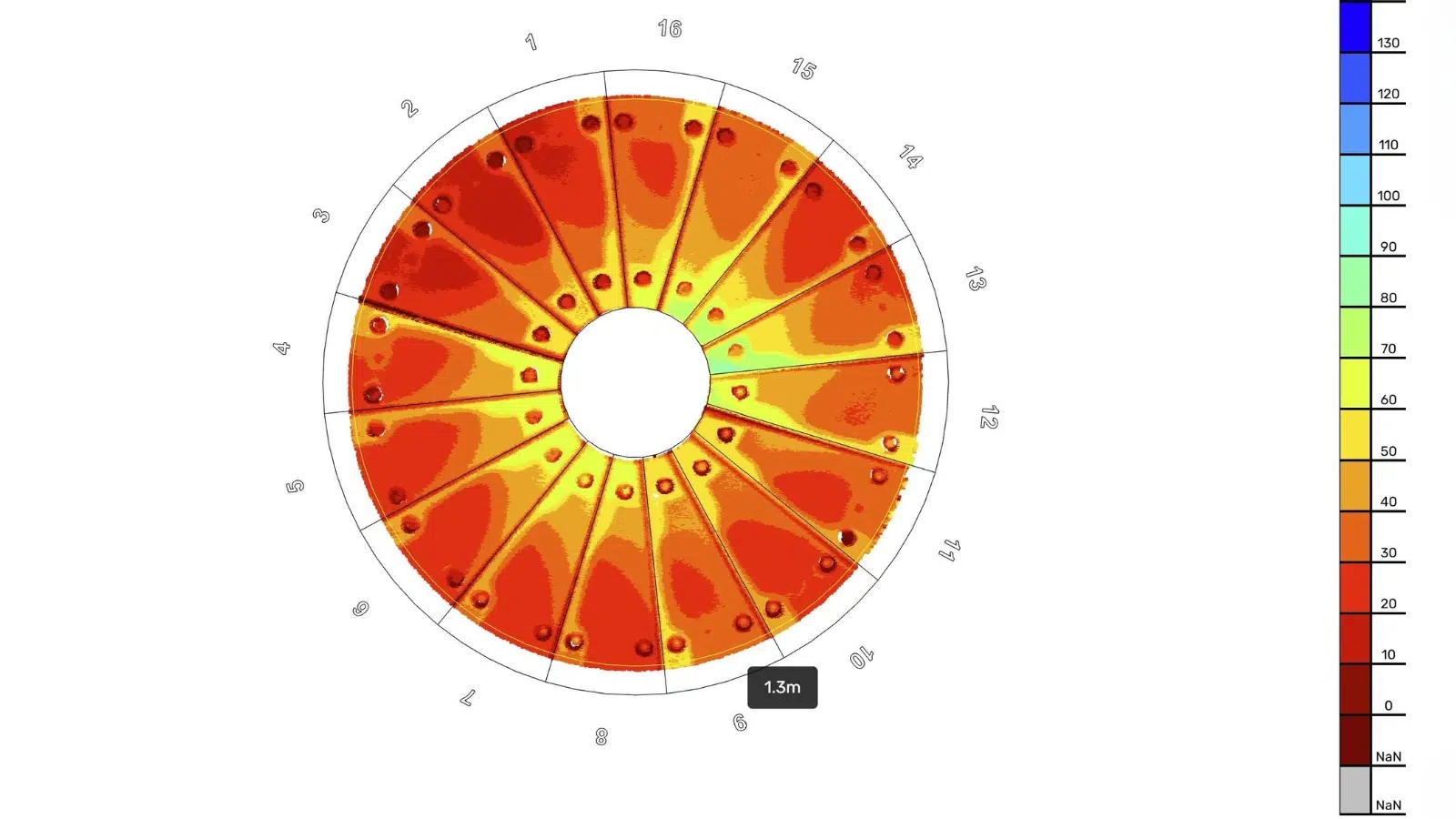

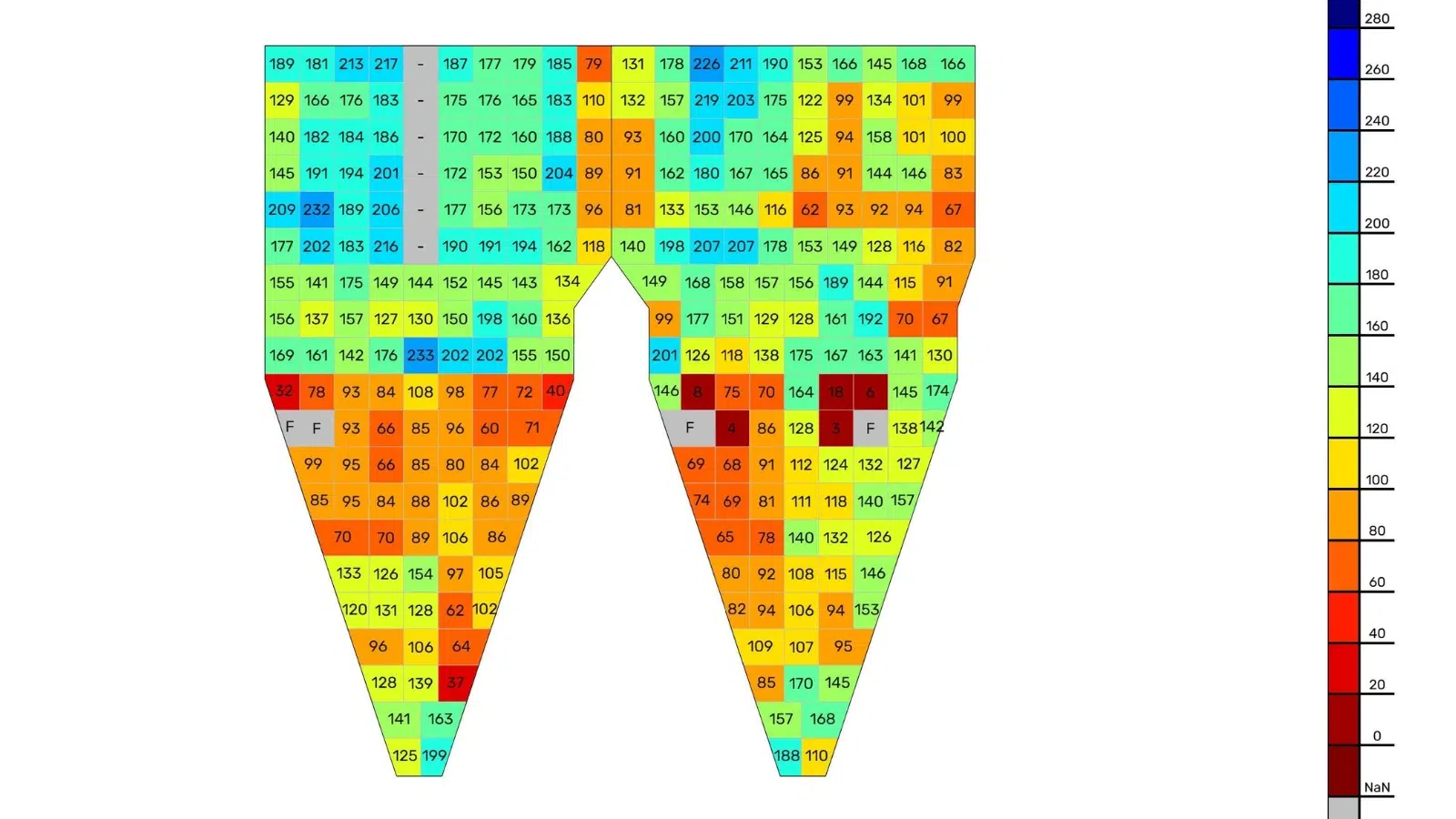

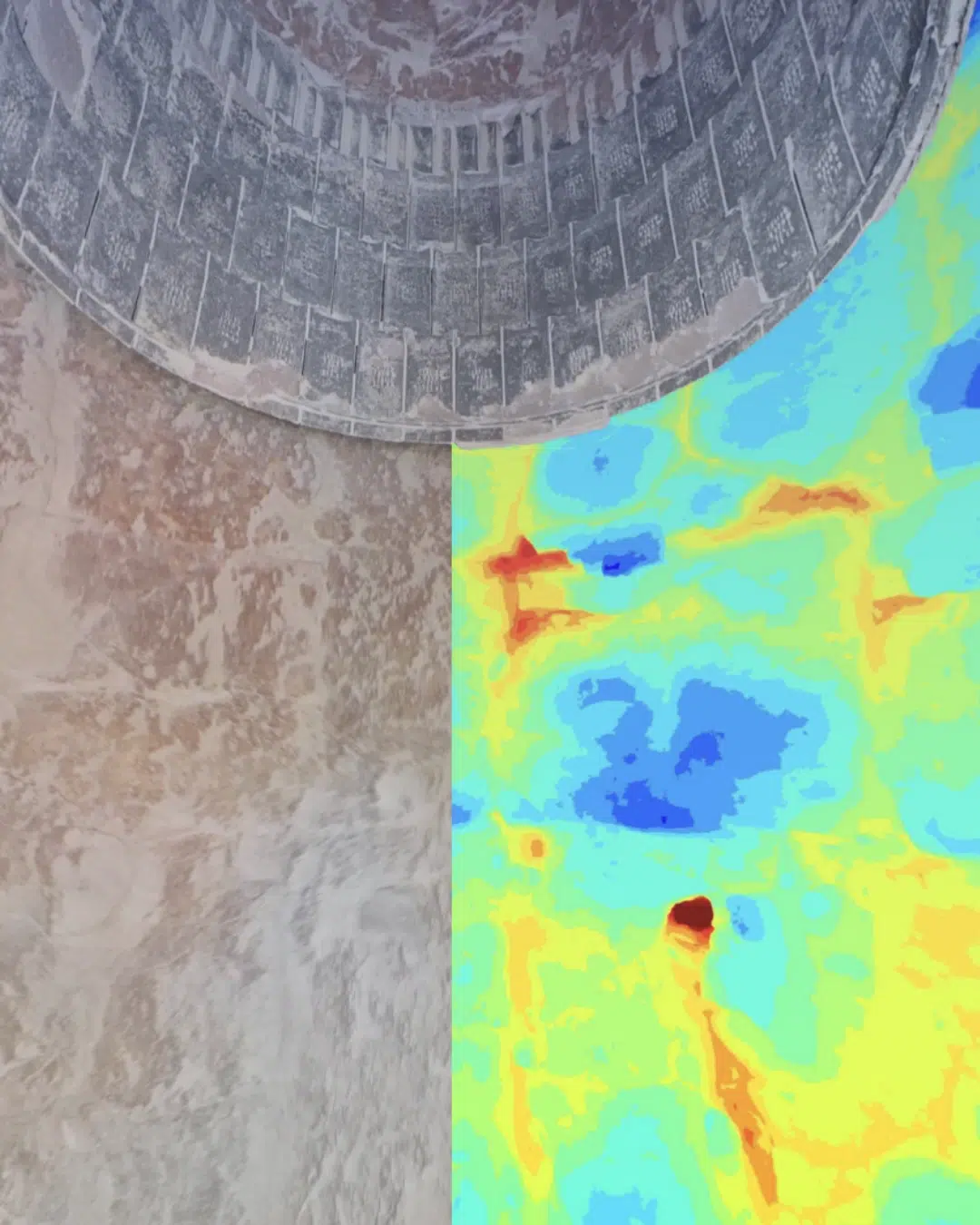

We capture every milimeter. Every surface. Every refractory and wear lining. Every critical component. No blind spots. No guesswork..

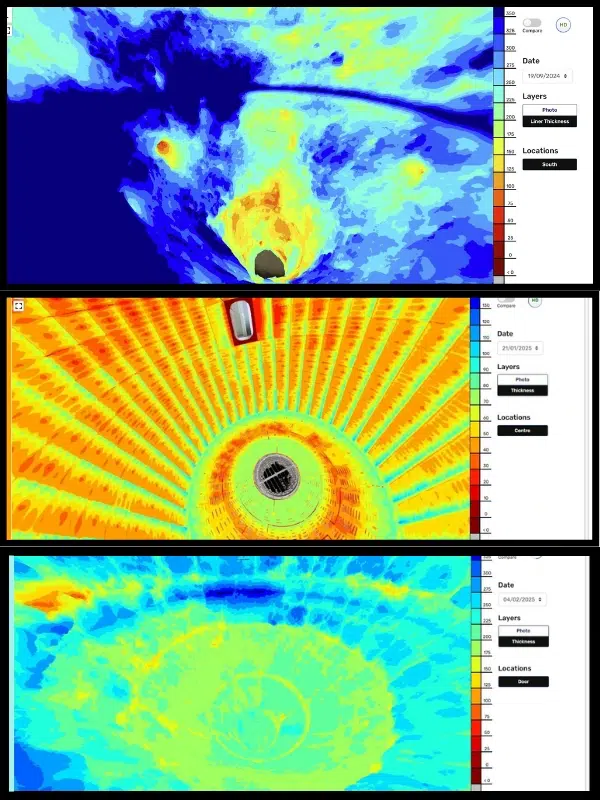

Step 2: Your Equipment’s Twin Comes Alive

Imagine watching your equipment’s future unfold before your eyes. Every scan creates an exact digital twin that spots tiny problems before they become disasters.

Step 3: Your Command Center Activates

Picture deep vision into every asset you own. One dashboard. Complete visibility. Total control.

Step 4: Where Data Meets Action

No “figure-it-out-yourself” reports. Just actionable solutions to prevent costly problems with your infrastructure before they happen.

Pick your industry’s biggest inspection nightmare:

Confined space entries? Refractory failures? Unexpected shutdowns?

Here’s how different operations eliminated theirs completely:

4DNA Industry Applications: Predictive Maintenance For Mining, Cement, Steel, and Beyond

Mining & Material Processing

Mining & Material Processing

Effectively Monitor your crushers, conveyors, and mills. Spot conveyor tears weeks before failure and catch transfer chute wear before it causes problems. (While your competition still waits for equipment to fail).

Cement & Steel Plants

Cement & Steel Plants

Refractory lining monitoring inside kilns and furnaces. Our advanced liner inspection system detects thinning and hotspots before costly blowouts occur.

Chemical Plants

Chemical Plants

Safely monitor your critical tanks and vessels remotely, so you can detect deformation and corrosion before leaks occur (…without risky confined-space checks)

Water Infrastructure

Water Infrastructure

Monitor critical assets without confined-space entry risks. Keep your water infrastructure running while detecting structural issues and wear patterns, so you can avoid costs.

And now for the million-dollar question… (literally) ↓

See 4DNA Predictive Maintenance In Action:

Your Next 30 Minutes Could Save You A Million

Book your DEMO and you’ll discover:

-

-

-

-

Plus, You’ll Get:

Uncover hidden equipment risks and get a complete vulnerability analysis of your critical assets.

Get your customized fast-track deployment plan to start preventing failures within weeks.

Discover what your current inspection methods are missing.

Click below to get started:

P.S. Still wondering if 4DNA is right for your facility? Consider this: The average plant loses millions to unexpected equipment failures every year. This FREE demo could help you prevent the next one.

want to discover how Wingfield’s 4DNA Predictive maintenance Can

“Future-Proof” your Operation?

Schedule Your FREE demo with a WINGFIELD 4DNA specialist!

Quality Asset Inspection Guaranteed

Trusted by America’s industry leaders since 1937: