Advanced Technology That Eliminates Measurement Blind Spots in Modern Mining Operations

You know the drill: trucks running underloaded or overloaded, equipment failures you never saw coming, stockpile counts that don’t match reality.

Every measurement blind spot bleeds profit.

Look, every mine faces the same measurement challenges.

The only difference is how much those measurement challenges will cost you… and how long you’ll wait to fix them.

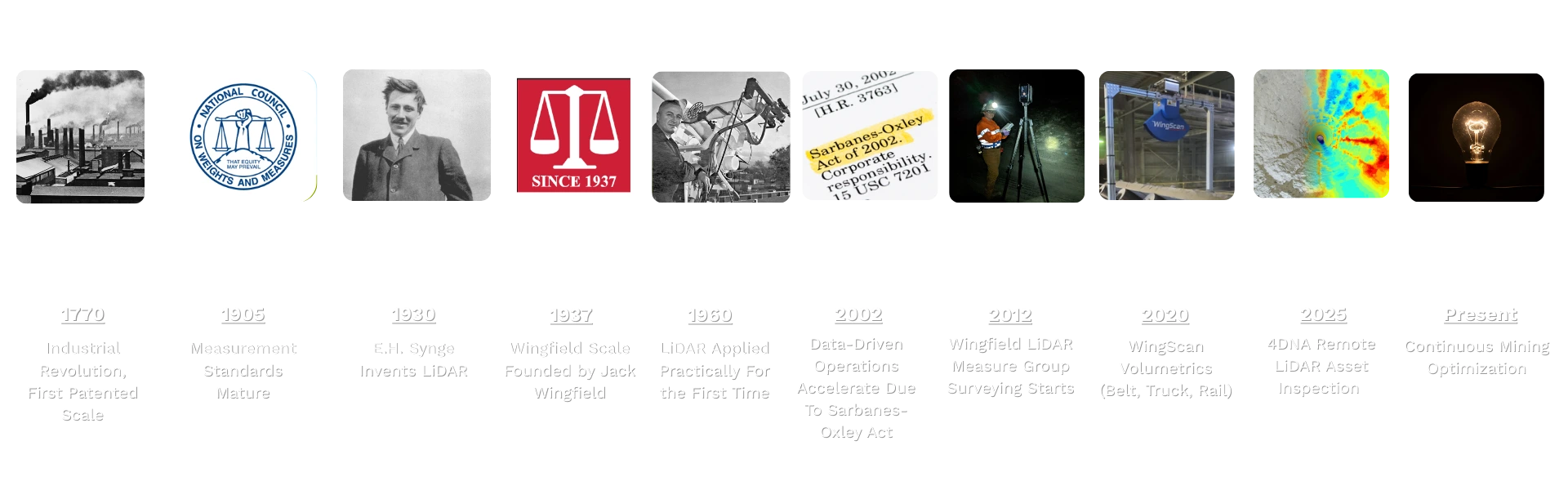

The mining industry has reached a turning point.

The mines pulling ahead eliminate measurement flaws entirely in ways that may surprise you.

Decades of experience has taught us one thing: what you don’t measure becomes cost. We eliminate measurement blind spots with a complete, connected measurement system.

What Modern Measurement Solutions Can Do For Your Mining Operation:

No More Bottlenecks

Fewer Disputes

Safer Operations

Optimized Payloads

Predictive Insights

Measurable ROI

What are the most profitable mining operations doing differently?

These upgrades are changing the game for mines across North America.

They fundamentally move how mining operations measure, monitor,

and optimize every aspect of production from A to Z.

Why Mining Operations Are Moving Beyond Traditional Measurements

Weight alone isn’t enough. Manual surveys aren’t fast enough. Periodic inspections aren’t predictive enough. Modern mining demands more.

These traditional measurement approaches were built for a slower era when downtime was acceptable and “close enough” was good enough…

That era is over.

Today demands comprehensive visibility across your entire mining operation: tighter margins, higher safety standards, and real-time insight across every asset and material flow.

The mines that thrive have figured out how to see everything, measure everything, and proactively act on everything.

So what separates them from the rest?

The Wingfield Advantage: Complete Measurement Solutions For Your Entire Mining Operation

Most mines cobble together incomplete measurement systems (truck scales for loads, manual surveys for stockpiles, reactive inspections for equipment, disconnected vendors for each)

Critical data gaps

Disconnected systems lose context between capture and reporting.

Coordination nightmares

Outages trigger finger-pointing while crews wait.

Delayed decisions

Latency between vendors slows production calls.

No accountability

When everyone owns a piece, no one owns the outcome.

Introducing One Integrated Platform To Measure EVERYTHING With Uncompromising Accuracy

Modern mining demands measurement across three critical dimensions beyond your typical strategies.

Here’s how Wingfield covers all three:

Proven Profits Across Mining Operations in North America

- Copper mine: Optimizing truck loads from 85% → 100% saved $0/day (~$1.9M/yr).

- Gold mine: Eliminating leftover material waste saved ~ $0/year.

- Aggregates: Cutting load disputes saved tens of thousands annually.

Choosing the Right Measurement Solutions for Your Mine

Different mining operations have different measurement needs.

Some need real-time load optimization. Others need predictive maintenance visibility. Many need comprehensive site intelligence—or all three.

The right combination depends on your specific operational requirements and where traditional measurement methods are costing you the most.

Consider these factors:

Current Measurement Bottlenecks & Pain Points

Current Measurement Bottlenecks & Pain Points

If queues, recalibrations, or disputed weights slow you down, start with real-time volumetric scanning. Click the link below to explore our multi-asset solution:

Compliance & Certification Requirements

Compliance & Certification Requirements

When your inventory and shipped material numbers feed into financial reporting, compliance lives or dies on measurement accuracy. Under Sarbanes–Oxley (SOX) , auditors care that your figures are consistent, traceable, and defensible over time.

That’s where controlling measurement upstream matters. WingScan measures bulk material volume as it moves (on trucks, belts, and rail) so you catch measurement errors and variability before they cascade into inventory, reconciliation, and reporting risk.

For operations that also need periodic reconciliation, WingScan can work in harmony with survey/mapping workflows. This gives you both real-time capture at the point of movement and verification across the broader site.

Extreme Weather & Conditions

Extreme Weather & Conditions

WingScan is engineered for temperature swings, dust, vibration, and continuous duty. Click the case study below to see how it performs in harsh mining conditions:

Critical Asset Maintenance Costs & Downtime

Critical Asset Maintenance Costs & Downtime

Unexpected equipment failures can stall production and drive up repair expenses. Monitoring wear proactively helps prevent costly breakdowns. Discover how to save your operation millions annually:

Long-term Operational Goals

Long-term Operational Goals

Planning a phased roadmap across volume scanning, mapping, and asset inspection? Click the link below to talk with a specialist:

Popular Measurement Resources For Mining Operations

The question isn't whether you need better measurement technology—it's whether you'll implement it before your competitors gain an insurmountable advantage.

Mining Measurement Solutions FAQ:

Do I need all three measurement technologies, or can I start with one?

Most operations start with their biggest pain point—whether that's load optimization (WingScan), equipment failures (4DNA), or stockpile management (UAV). Each solution delivers standalone ROI, but they're designed to integrate as your measurement needs expand.

How is your approach different from traditional measurement methods?

Traditional methods—scales, manual surveys, periodic inspections—measure your operation in disconnected pieces.

We integrate three technologies (volumetric scanning, remote asset inspection, UAV mapping) into one platform that captures material flow, asset condition, and site intelligence simultaneously.

It's complete visibility, not fragmented data.

How quickly do your solutions pay for themselves?

Most operations see ROI within months via reduced downtime, optimized loads, and fewer measurement disputes.

View specific ROI scenarios from real mining operations →Interested in Discovering More About Wingfield's Mining Measurement Solutions?

Schedule a conversation with a Wingfield specialist!

or call 423-698-0100