You might be on this page right now wondering, “What the heck is a mining load scanner”? “How can this thing help our mining operation”? “How rugged is it”?

These are all great questions.

Let’s dig in ⛏️💎 (pun intended):

Your mining operation happens in really tough places.

There can be super hot or cold weather, tons of dust, strong shaking, and even heavy rain or snow.

In harsh mining conditions, accurately measuring the amount of material hauled by your trucks and/or moved along your conveyor belts can mean saving millions of dollars.

Our WingScan Mining Load Scanner is built just for these hard jobs.

It’s designed always to give correct measurements (…even if you’re standing in a dust storm or working through pouring rain).

Now, you might be wondering, “what makes accurate measurement so critical that it’s worth investing in advanced technology like this“?

The Critical Factor Most Mines Miss: Accurate Mining Load Scanner Data

Every mining operation depends on one critical factor that most overlook.

What is that factor?

In mining, knowing EXACTLY how much material you move every day matters A LOT.

Accurate data helps mines make more money. It keeps operations smooth and workers safe.

And stuff like your quarry truck hauling isn’t your only concern here.

Materials also move constantly on conveyor systems.

Both your trucks and conveyor belts must deliver precise measurements simultaneously to keep your operation profitable and running smoothly.

Think about it for a moment..

Every time you shut down for belt scale calibration, you’re potentially losing $3000 per hour in stopped production.

Those truck bottlenecks at your platform scales? Each 5-minute wait costs you $180-250 in idle equipment time.

Multiply that across 50 trucks per day, and you have serious problems that snowball even more as time moves on.

In short, your mines MUST get measurements right to gain a clear competitive advantage (especially in those extreme environments where traditional scales struggle to function).

So what exactly makes these environments so brutal for measurement? Let me paint you the real picture of what your equipment faces every single day.

Why Harsh Mining Conditions Demand a Bulk Material Scanner

Here are the struggles your traditional mining equipment usually faces:

Your equipment is choking on grit, giving you readings that are off by thousands of pounds.

Mines can be very hot or very cold, hurting equipment if it’s not strong enough.

Heavy equipment and explosions shake the ground, messing up most measuring tools.

Rain, snow, and damp air can damage equipment and make it stop working or throw off scale calibrations.

Imagine the variety of extreme conditions you can encounter in a mine: Clouds of dust swirl around you, choking the air and making it impossible to see clearly.

The sun beats down mercilessly, heating metal surfaces until they’re almost too hot to touch—or maybe it’s a biting cold that freezes some of your equipment parts solid.

Each blast from explosives sends shockwaves through the ground. They rattle every bolt and hinge.

Rain pounds down.

It turns the ground into slippery mud and fills every opening with water.

In these moments, regular measuring tools simply don’t stand a chance.

Over time, they wear out and break down. And when that happens, it grinds your operation to a halt.

You need something built for this exact challenge if you want to avoid constant setbacks with your measuring system.

How WingScan Effectively Handles Your Measurements (…Even In Extreme Conditions)

Now, you might be wondering, ‘What makes this different from every other mining volume scanner that’s promised the moon?’

Here’s Why We’re The Leading High-Tech LiDAR Truck & Conveyor Scanner Providers For The Mining Industry

Here’s the thing about WingScan’s LiDAR technology – it’s like having laser radar that works when everything else fails.

While other scanners choke when visibility drops to zero, WingScan keeps delivering pinpoint measurements through conditions that would blind traditional equipment.

How?

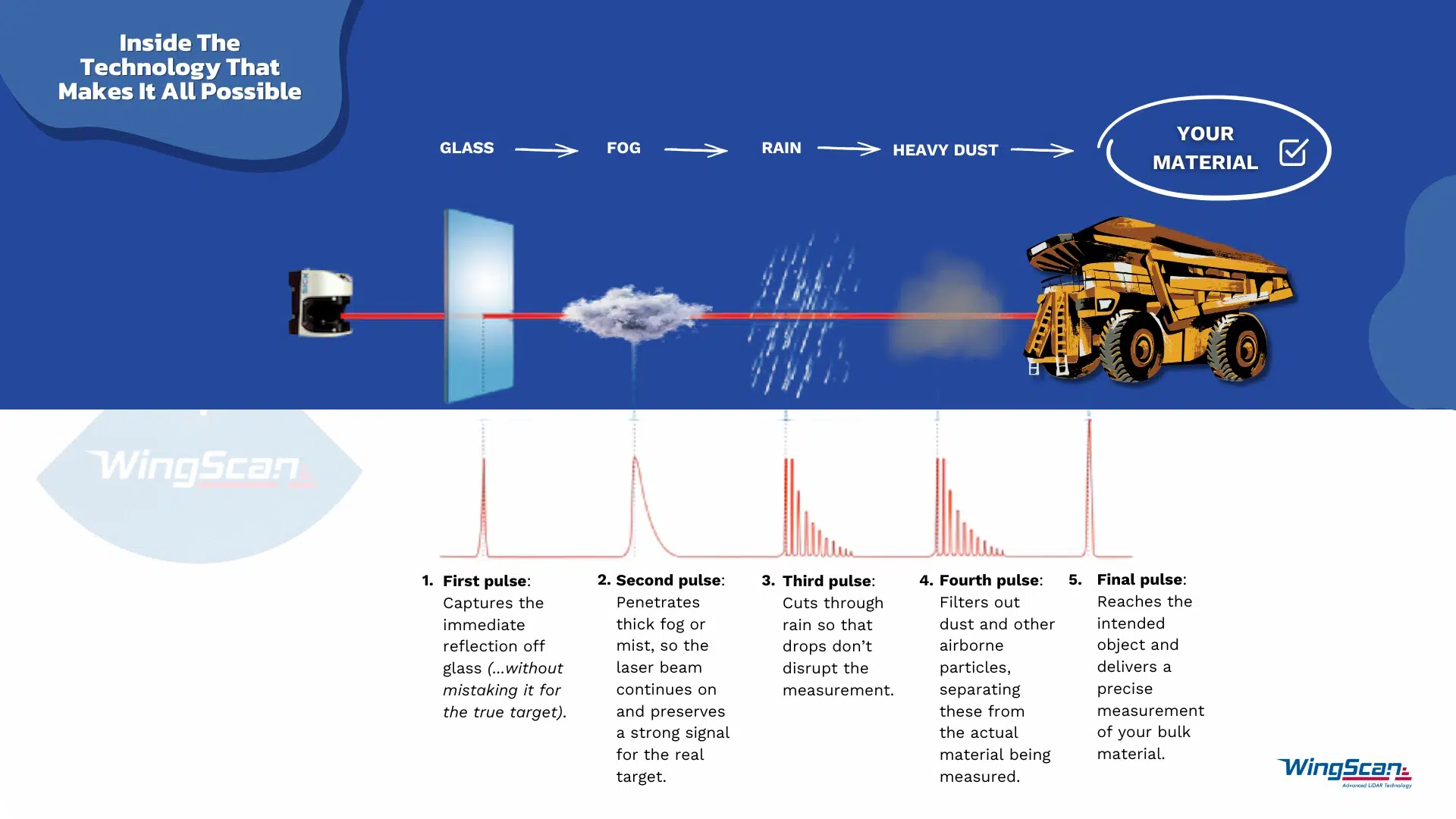

The secret is SICK ECHO 5 Technology

Think of it like this: You know how a flashlight beam bounces off whatever it hits?

WingScan’s system does the same thing, but with incredibly precise laser pulses.

When our lasers hit something – could be dust in the air, could be a glass window, could be fog – they bounce back.

We call that laser bounce-back an “echo.”

Now, here’s the thing…

Our system can handle multiple echoes simultaneously.

Why’s that such a big deal?

Because in the real world, where you’re actually working in harsh environments, that laser pulse hits all sorts of stuff before it reaches your material – glass, fog, heavy dust, rain, you name it.

Here’s how SICK ECHO 5 Technology cuts through the chaos:

This infographic illustrates how WingScan’s SICK ECHO 5 system uses five laser pulses to handle challenges like glass, fog, rain, and dust before reaching the actual material for precise measurement. Each pulse targets a different obstruction layer, shown visually with waveform data and labeled stages beneath the laser path. The result: accurate bulk volume readings even in the harshest mining environments.

In other words, our system automatically filters out all the junk to find your material (…without needing to rely on belt scales, weighbridges, platform scales, or excessive maintenance).

But intelligent measurement technology is only as good as the hardware that houses it, and that’s where WingScan’s military-grade construction becomes your secret weapon.

The Strongest Bulk Material Scanner For Mining Conditions

Besides enabling you and your team to measure obstacles in the way accurately, our engineers also spent years crafting WingScan with the durability of a military-grade machine.

Its industrial-grade metal housing and fully sealed, IP67-rated enclosure withstand blistering heat up to 140°F and freezing cold down to -40°F.

It is impervious to harsh dust storms and relentless rain.

In other words, it delivers you precise and reliable results day after day (…no matter what Mother Nature throws at you).

Read how WingScan load scanning delivers profit for mining operations in our ROI case study .

FAQ About Our Volumetric Scanners For Mines:

How does a mining load scanner handle vibrations from blasting?

Many truck load scanners struggle with shockwaves from blasts and heavy equipment, causing erratic readings and forcing frequent recalibration. Our mining load scanner uses shock-absorbing mounts and reinforced hardware to filter out these vibrations—delivering rock-solid accuracy after every blast.

(No more chasing phantom readings—even in harsh mining conditions)

Is a mining load scanner worth the cost?

Absolutely—especially when you consider the cost of downtime and maintenance with traditional truck scales. A typical scale may need $500+ in repairs every month, plus thousands in lost productivity during downtime. Our volumetric load scanner for mining operations has no moving parts, so maintenance is minimal and downtime nearly disappears. It often pays for itself within months.

(Keep tens of thousands in your operation instead of losing it to breakdowns)

What makes your mining load scanner better than other options?

Our LiDAR truck scanner is built for uptime, accuracy, and ease of use:

- No moving parts = virtually no maintenance

- Fast setup = quicker ROI

- Accurate in all conditions—dust, rain, fog, and vibrations

- Supported by expert training and responsive support

(It’s the volumetric scanner top mining operations trust to maximize output and minimize downtime)

Does this bulk material scanner work for all types of mines?

Yes. Our bulk material scanner for sale is proven in all major mining environments, including:

- Underground tunnels

- Open-pit mines

- Coal, salt, and aggregate operations

- Heavy mineral extraction

- Diamond and gold mines

(This volumetric load scanner is engineered to thrive wherever you need reliable measurements)

Why A Volume Scanner Is A Smart Investment For Your Mining Operation

Ultimately, getting accurate measurements means mines can save money, keep workers safe, and make more profits (…without added safety risks, downtime, or scale hassles)

WingScan is made specifically to handle tough mining conditions and gives mines accurate data day and night. Want to see how WingScan can help your mining operation?

Contact us today to learn more, get pricing, or schedule a demo.

Read how volumetric scanning delivers ROI in the real world in our ROI case study .

Interested in learning how Wingfield can help your business?

Schedule a conversation with a wingfield specialist!

or call 423-698-0100