Underground Total Station Services

Wingfield offers underground total station services for setting control, updating alignment, and combining the total station control data with LiDAR scanning data.

Related Case Studies

Room and Pillar Scanning

Using static and dynamic LiDAR systems we are able to map, measure, and track room and pillar progress. LiDAR and processing data allows for enhanced visualization of areas of interest and more precise volumetrics.

Mine Shaft Scanning

Shaft scanning has been used for rehab, repairs, change detection, and historical mapping. The ability to mount our dynamic LiDAR system to a cage and map shafts effectively, safely, and quickly means lower amounts of downtime in hoist operations.

Underground Structure Scanning

With the ability to scan and map with high resolution gives Wingfield expertise in structure scanning not only on the surface but underground. Making upgrades to structures or creating blueprints that can be accessed anywhere saves time and money.

Autonomous UAV LiDAR Scanning

This UAV can be manually or autonomously flown to map areas that are inaccessible or lack the structural integrity for safe entry. It is commonly used for stopes and voids, failing and older or abandoned working areas, and for basic inspection.

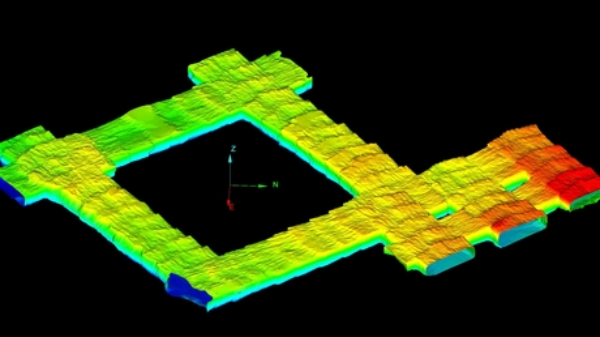

Underground Room and Pillar Example

A sample of a room and pillar point cloud and rendered surface used for volumetric calculation, as-built vs design, convergence, mine design updates, and more!

Underground Maintenance Shop Example

A processed and scanned underground maintenance shop that was being measured for dimensions and clearance checks for new and existing equipment.

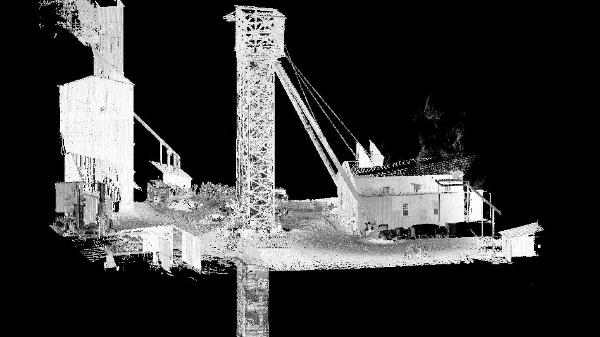

Shaft Scanning with Timber Sets

Point cloud data captured in one hour on a two-compartment 2,000ft timber lined shaft. Data is used for rehabbing, documentation, change detection, and scoping purposes for other contractors.

Large Pillars and Change Detection

Large underground mines with high roofs or backs can be challenging to check for changes or movement. The LiDAR systems used by Wingfield can scan to a range of 600 meters underground and provide real data that can be compared overtime to track movement.

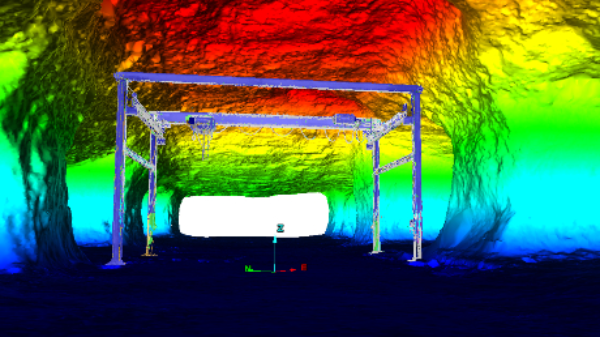

Underground Crane Example

Planning upgrades for underground but need to be sending information to contractors on placement of equipment or measurements? Digital twins allow you take measurements in software and avoid the cage ride to check on a measurement.

Professional LiDAR Scanning

The ability to use various LiDAR and UAV technologies in the field allows us to rapidly capture data in adverse conditions while maintaining timelines for quarry updates or stockpile inventories.

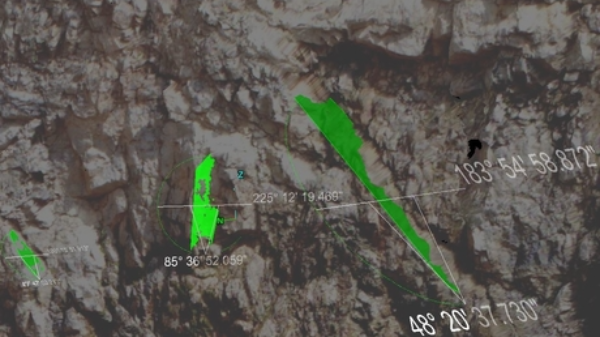

Geotechnical Data Capture

High resolution georeferenced data can be captured and processed ready to import into various geotechnical software packages.

Autonomous LiDAR UAV/Drone

Using our Autonomous UAV/Drone to examine abandoned mine travel-ways allowed our client to understand and mitigate hazard before exposing men and machines. The video-LiDAR displayed critical, otherwise inaccessible data available to decision makers.

Introducing WingScan-B

The premier maintenance-free solution that delivers real-time volume and mass flows on each conveyor belt. Connect, monitor and command each system via secure and intuitive controls on mobile or desktop, or easily connect to a variety of PLC systems.

Interested in learning how Wingfield can help your business?

Schedule a conversation with a Wingfield specialist!

or call 423-698-0100

Wingfield helped us overcome some problems and obstacles we had and didn’t flinch. It’s refreshing to see someone take that on. They see the bigger picture.